Intelligent, lightning quick, and safe: software opens new opportunities

The automotive world is developing rapidly. With the DTM Electric Democar, Schaeffler is at the forefront of this development. The prototype fully-electric touring car completed a total of 13 laps without a driver in Spielberg. The ‘remote run’ not only shows how advanced the technology behind the DTM Electric already is – it is also an indication of what smart software and system integration can achieve in production cars in the future.

More than the sum of its parts

Today’s cars are far more than just the sum of their parts. High-quality components and systems, exclusive equipment and state-of-the-art technology remain the basis for an automobile. However, to ensure that all these elements provide the desired function at the right time, or do not get in each other’s way, you need smart controls. This is where software comes into play – a discipline which is now integral to the everyday work at Schaeffler and is also growing in importance all the time in motorsport.

In production development, the control system software and modern hardware, in particular, contribute to ensuring that individual vehicle components now perform better than they did a few years ago. Schaeffler implements software solutions in many areas, including e-axles with power electronics, which also integrate functions like parking lock and actuating systems, as well as safety and comfort functions.

Software as an invisible assistant

Many of these software solutions have now become so common that they are no longer even consciously perceived in everyday driving. One example of this is the smart control of the coolant pump in the field of thermal management, ensuring that the desired temperature is always achieved in the interior. Another example is the energy strategy in electric vehicles, which recommends deactivating unnecessary power consumers when battery charge is low to maximise range. It can often be said that the less visible the software, the better it has been integrated in the car. Schaeffler software solutions already cover virtually every vehicle system.

A decisive step in software solutions being elevated to essential elements in vehicle construction is the increasingly important electrification and digitalisation within the car. The DTM Electric Democar is already showing what opportunities this development provides.

DTM Electric completes driverless laps

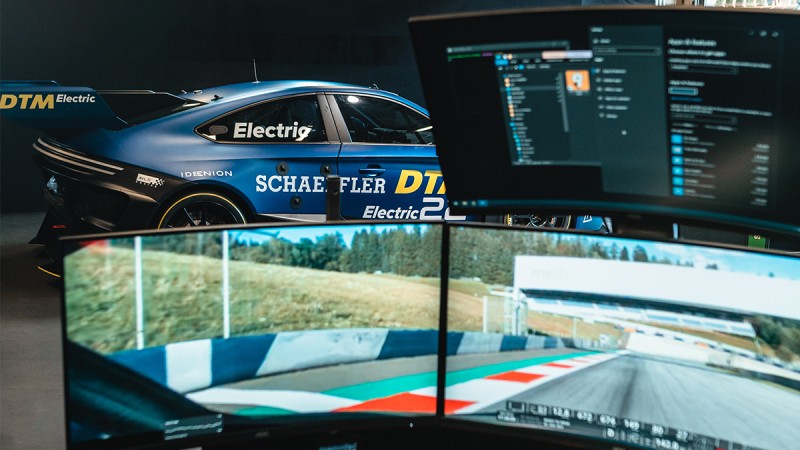

It is more than just the all-electric prototype of a possible electric touring car series, it also has technology – and software – on board, which will have a crucial influence on the future of our mobility. Schaeffler showed an aspect of this with the DTM Electric Democar during the DTM race weekend in Spielberg.

At the Red Bull Ring, the all-electric race car completed demonstration laps without a driver at the wheel. The DTM Electric Democar was driven by DTM Trophy champion Tim Heinemann. He was sat roughly 80 kilometres from the racetrack, in Graz, where he drove the 1,200-hp car via a simulator using 5G technology.

Drive-by-Wire as key technology

As well as the software controls, this is primarily made possible by drive-by-wire technology from Schaeffler. As well as the steering, it also controls the car’s brakes electronically, instead of mechanically as was previously the case. As such, the system provides the basis for autonomous driving. The ‘remote run’ of the DTM Electric Democar showed emphatically how sophisticated the Space Drive technology already is, and what it can achieve, even in extreme motorsport conditions, whilst still adhering to all safety measures.

Together with partner companies from all over the world, it took Schaeffler just five months to achieve the driverless appearance of the DTM Electric Democar. Project leadership, system integration, the key technology of the drive-by-wire system, the safety concept and the execution of the demonstration laps were in the hands of Schaeffler employees.

Focus on safety, eyes on the future

Not only must completely new components like cameras, antennas and high-performance modems for wireless data transfer to the car be integrated, but solutions to all risk scenarios that naturally come with such a pioneering drive must also be found. For example, if the signals from the simulator had arrived in the DTM Electric with a delay of just over 100 milliseconds, the system would have shut down for safety reasons. Just like at the racetrack, every fraction of a second counts when it comes to motorsport software.

Events like the ‘remote run’ in Spielberg underline the fact that the DTM Electric Democar can not only set benchmarks in motorsport, with a drive configuration that is revolutionary for touring car racing, but it can also provide an indication of the future of production automobiles. After all, drivers will continue to make the difference at the racetrack in the coming years. On the streets, however – and particularly in many special areas – digital functions can have many benefits.