Stories from Schaeffler

Take a tour through the world of Schaeffler and find out what contribution Schaeffler's solutions are making for the mobility concepts of today and tomorrow.

In Focus

Green products – for the environment and the success of the company

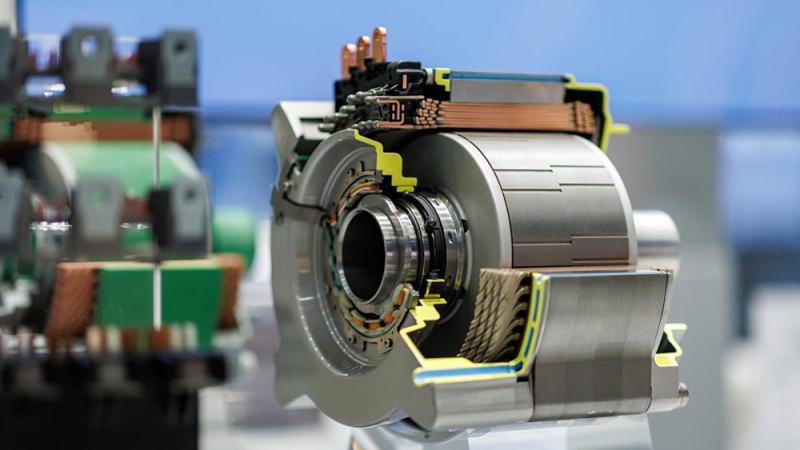

The transformation of mobility towards climate-friendly drives is also reflected in Schaeffler’s product portfolio. Green products are found in many areas, from vehicles to machinery and wind turbines. They benefit people and the environment but also secure competitive advantages. This is why CO2-efficient drives play an important role in Schaeffler’s automotive business.